Without causing tissue trauma, a small endoscopic probe is a necessary equipment for imaging small cavities or fragile organs. However, current manufacturing methods limit the imaging performance of highly miniaturized probes, thereby limiting the wide application of small endoscopic probes.

Researchers from the University of Adelaide School of Medicine in Australia, the Institute of Optical Advanced Sensing, the Institute of Applied Optics (ITO) and the SCoPE Research Center of the University of Stuttgart in Germany, have developed a new type of ultra-thin technology through two-photon lithography micro 3D printing technology The probe device directly creates lateral free-form micro-optics on a single-mode fiber (thinner than a human hair). According to the researchers, this is the smallest free-form three-dimensional imaging probe reported so far. The entire endoscope with a protective plastic casing has a diameter of 0.457 mm.

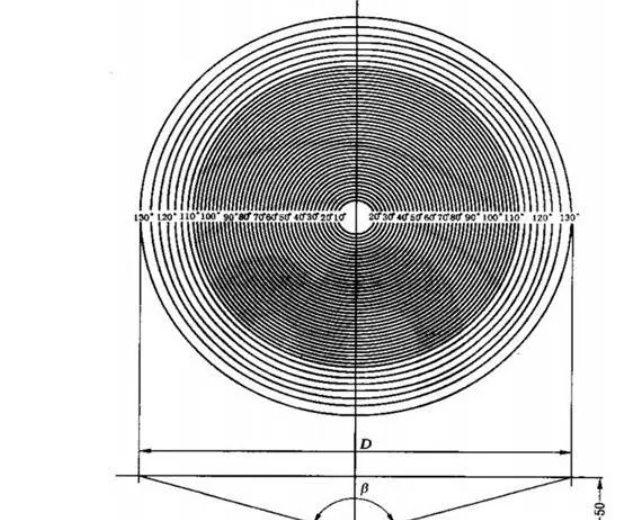

The current probe manufacturing technology has problems of spherical aberration, low resolution or shallow depth of focus when manufacturing highly miniaturized probes. In optical design, high resolution (large numerical aperture, NA) needs to be weighed, which results in rapid beam divergence, small focus depth, and poor resolution (small NA), which makes it impossible to achieve a large focus depth. In optical coherence tomography imaging, because the endoscope and intravascular probe are deployed in a transparent catheter sheath, it not only protects the animal or patient from trauma when the probe is rotated for scanning, but also prevents repetition between multiple animals Cross contamination during use.

Optically, this transparent sheath is equivalent to a negative cylindrical lens and causes astigmatism. Astigmatism increases the attenuation of the lateral resolution of the miniaturized probe. Therefore, the correction of these non-chromatic aberrations is essential to obtain the best possible resolution at the desired depth of focus with the micro probe, and the current micro-optical manufacturing methods lack the ability to reduce these non-chromatic aberrations. Researchers have developed an ultra-thin single-piece optical coherence tomography endoscope, which overcomes these limitations by using two-photon polymerization 3D printing technology to print 125-micron diameter micro-optical devices directly onto optical fibers.

During the development process, the researchers spliced a 450-micron coreless fiber to a 20-centimeter-long single-mode fiber and expanded the beam before it reached the 3D printed free-form micro-optics. In order to realize the splicing of this coreless fiber, they first spliced a longer coreless fiber to a single-mode fiber, and then used an automatic glass processor and an in-line cleaver to cut it to 450 ± 5 microns. The role of the two-photon lithography 3D printing technology is to print the beam shaping micro-optics directly to the far end of the coreless fiber.

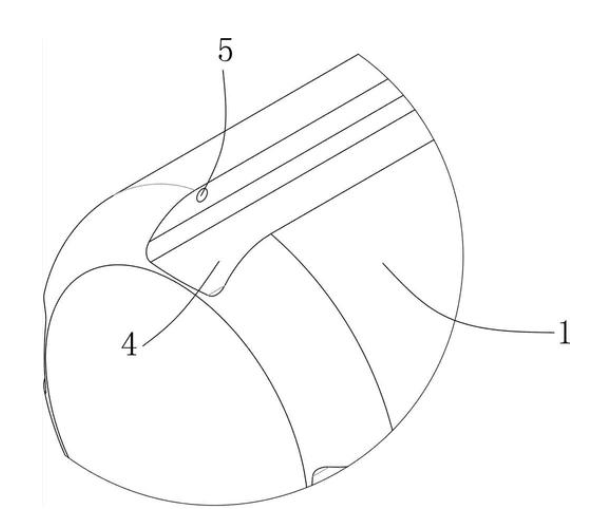

The free-form surface of the 3D printed micro-optical device changes the direction of the beam through total internal reflection and focuses the beam. The optical fiber assembly is fixed in a thin-walled torque coil with an outer diameter of 0.36 mm. The torque coil allows rotation and linear motion to be accurately transmitted from the proximal end of the imaging probe to the distal end, thereby realizing 3D scanning. The 3D printed miniature imaging probe rotates freely in the catheter sheath, and the catheter sheath remains stationary and protects the biological tissue during the 3D scan.

![]() Phone Number:0755-26943630

Phone Number:0755-26943630![]() Phone Number:0755-26943630

Phone Number:0755-26943630

![]()